IDECO Heavy Equipment kft

Szabadság utca 75

7918 Tótújfalu

Hungary

+36 70 522 1235

Engineering Company

Steel Industry

Material Handling

Minerals & Mining

IDECO Mining and Metallurgy Inc.

Str. Depoului, nr. 16

Ploiesti, Jud. Prahova

100335 Romania

+40 75 368 2658

Mechanical engineering consulting.

Mechanical performance optimization.

Mechanical reliability engineering.

Mechanical failure analysis.

Mechanical system diagnostics and improvement.

Mechanical reverse engineering.

IDECO is an independent engineering company specializing in mechanical engineering consulting, especially focusing on Performance Optimization and Failure analysis.

We provide an effective and powerful way to manage your projects for bulk material handling, metallurgy, oil&gas, and pressure vessels.

Skills and professionalism

Know-how and software

Trust and reliability

What IDECO Group does

Our mechanical engineering activity completely covers the stages of study, calculation, design, control of the manufactured project, and any further modifications and optimisation so that the customer's requirements can be completely satisfied. We guarantee continuous improvement of the project even after its realisation and during its lifetime. Our task does not end in the technical office, but it ends when the machine is decommissioned.

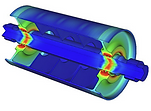

When very sophisticated tools, like 3D software and FEM / DEM software, are used for designing, a machine or a component acquires very specific features that can obviously meet difficulties during manufacturing and can lead to mistakes in production and consequently defects and failures.

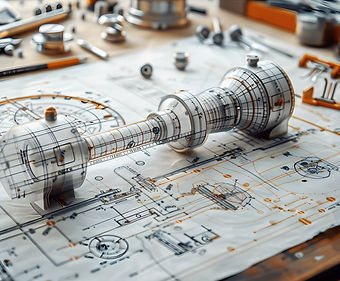

The first phase of the project ends in our offices where we produce the scaled model with professional 3D printers, thus materially verifying the result of our job.

Once the first part of the design is sent to the workshop where it gets realised, while for most engineering firms the job ends, for us the second phase starts, which is the most important for the customer. Thanks to our latest generation measurement tools combined with software for metrology and reverse engineering we can check that the manufactured component really corresponds to the designed one; by using 3D scanner and UT thickness meter (both certified measurement tools) we are able to virtually recreate the component; thanks to our metrology software we compare the initial 3D model, as designed at the beginning of the project, with the manufactured model, as scanned by us; in such a way, we can verify that the theoretical dimensions, the dimensional tolerances and the geometrical ones have actually been respected. After this first geometric check, we verify that the used material has the characteristics indicated in the calculation report; this test is made with non-destructive RX metal analyser and digital hardness meter that allows us to compare the chemical analysis with the mechanical characteristics.

We use our ultrasound flaw detector to inspect welds and materials so that we can determine if the component class can is respected or if we need to modify the component avoid lowering its class.

Then, we detect that the hardness and roughness of the surfaces correspond to those indicated by the designer.

When all the inspections on components are done, we can check the assembled machine by detecting that noise and vibrations respect the design technical specification and the project itself. Then, with our thermal imaging camera we check for overheating due to mechanical phenomena or overheating of liquids or electrical cables due to the Joule effect. These measurements will be an addition to the project calculation report so that the customer can have a thorough image of the manufactured machine.

Summarizing, we offer a three-phase engineering process:

-

We issue all the documents to be sent to the workshop for manufacturing – we call it OFFICE PHASE

-

We check that the project is well manufactured and that the machine corresponds to the customer’s needs – we call it WORKSHOP PHASE

-

We make a design review to accompany the machine life so that the machine supports the production according to the customer’s needs – we call it PLANT PHASE.

When the customer finally decommissions the machine, our project will end.

That’s IDECO Group!

With the Right Software Great Things Can Happen

At IDECO we are supported by the right software for mechanical design so that we can get the best from our know-how and easily transform our knowledge into projects. Belt conveyors and bulk material handling in general have their dedicated technology with SIDEWINDER, PAX FEA and DEM NEWTON PROFESSIONAL. Calculations are made with CSI SAP 2000 (for machines and steel structures), FE-System MEANS V13 (for mechanical components and machines), CRANEWAY (for crane runways). Pressure vessels and heat exchangers are analysed and designed with MICROTECNO. 2D/3D drawings find their best expression in BricsCAD Ultimate, Mech-Q and TecnoMETAL. Calculation reports and manuals have their suitable tools in MATLAB, SIMULINK, CorelDRAW Technical Suite. Finally, we manage the laser 3D scanner (for metrology) and the structured light 3D scanner (for reverse engineering) thanks to GEOMAGIC Enterprise that includes Geomatic Design X Full, Geomagic Control X Full, Geomagic Wrap.

What We Offer

IDECO Heavy Equipment is dedicated to offering specialized engineering services to customers, combining expertise and the best technology to drive excellence in every project.We take pride in our commitment to differentiate our offering.

Mechanical Engineering Consulting

Expertise and technological tools applied to engineering process are our concept.With over 30 years of experience we make our capabilities and know-how available to customers, whether they deal with bulk material handling, metallurgy or oil&gas and pressure vessels.

Moreover, 3D printing can be the right outcome of a model for prototyping or just for commercial purpose.

Reverse Engineering

The key points of our activities are:

-

Making machines more efficient and effective

-

Focusing on preventing breakdowns, and identifying weak points to improve the overall reliability of the system

-

Determining the root cause of a malfunction

-

Diagnosing issues within a system and working to improve its overall function.

This means that with the final scope in mind, we go through the documents of an existing machine and provide the customers with calculation reports and drawings allowing them to get higher performance from their machines.

Reverse engineering involves deconstructing existing products to understand their design and functionality. This technique is sometimes crucial for maintenance and repair. When original design documents are unavailable, reverse engineering allows us to recreate parts or improve existing systems. 3D scanning together with XRF analyzer, UT instruments and more facilitates this process by providing accurate digital models of the components, which can then be analyzed and reproduced.

IDECO Global NDT

We take the 3D design to a higher level.

After manufacturing, we check if the produced part really corresponds to the drawing by scanning it using our:

-

Structured-light 3D scanner

-

Laser 3D scanner

And by measuring it using our:

-

Handheld XRF analyzer for metals

-

Digital hardness tester

-

Ultrasonic material thickness gauge

-

Roughness tester

-

Digital ultrasound flaw detector

-

Other laser instruments for measuring linear quantities and environtmental quantities.

🌐 CES™ – Structural Energy Coefficient

A new proprietary methodology developed by

IDECO Heavy Equipment Kft

What is CES™

The CES™ (Structural Energy Coefficient) is an innovative and proprietary engineering methodology created by IDECO to evaluate the real structural condition of machines, plants and infrastructures through a single unified metric.

Why CES™ was developed

Modern industrial and infrastructural assets operate under complex conditions:

-

variable mechanical loads

-

high temperatures

-

vibration and dynamic stresses

-

environmental exposure

-

long-term degradation

Traditional evaluations analyse these effects separately, making it difficult to obtain a global understanding of structural safety.

CES™ provides one unified interpretation, readable by engineers, managers and decision makers.

How CES™ helps

CES™ enables:

-

early identification of anomalous behaviour

-

improved risk management

-

reduction of extraordinary maintenance

-

simplified decision-making at technical and managerial levels

-

consistent comparison between different assets

-

enhanced planning for repairs, upgrades and investments

-

integration with FEM, sensors, SCADA and digital twins

Where CES™ applies

Industrial assets

-

steel and metallurgical plants

-

high-temperature structures

-

pressure equipment

-

rotating machinery and large mechanical systems

Material handling & port equipment

-

stackers, reclaimers, shiploaders

-

bucket-wheel machines

-

conveyor systems

-

port and bulk-handling facilities

Infrastructure

-

bridges and viaducts

-

rail and road structures

-

port infrastructures

-

large-scale civil structures

Governmental and strategic projects

-

smart cities

-

industrial development zones

-

mega-projects and public infrastructures

-

energy and water infrastructure

What makes CES™ unique

-

proprietary methodology developed by IDECO

-

protected by official registration (Patamu No. 274071 – 2025)

-

independent from software or hardware

-

compatible with all engineering standards (EN, ISO, ASME, Eurocodes…)

-

applicable across all sectors

-

simplified interpretation through a universal A–F scale

What IDECO offers

CES™ Assessment

Evaluation of an existing asset using the CES™ methodology.

Output: A–F classification + summary findings.

CES™ Licensing

Access for corporations and governmental bodies to use the methodology across multiple assets.

CES™ Integration

Support for integrating CES™ into digital twins, monitoring systems and asset-management platforms.

CES™ Institutional Proposal

Dedicated programs for ministries and public authorities.

-

proprietary methodology developed by IDECO

-

protected by official registration (Patamu No. 274071 – 2025)

-

independent from software or hardware

-

compatible with all engineering standards (EN, ISO, ASME, Eurocodes…)

-

applicable across all sectors

-

simplified interpretation through a universal A–F scale

Request a presentation

To learn more about CES™ or to schedule a technical or institutional presentation:

📩 Contact:

IDECO Heavy Equipment Kft

Email: ideco@ideco.group

PEC: marcobandini@pec.perind.it

Case History

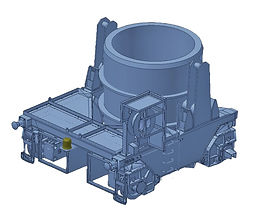

Ladle Car Project:

A Comprehensive Approach to Design, Verification, and Innovation

1. Introduction

In the modern steel industry, the efficient and safe transport of molten steel is critical. Our "Ladle Car" project represents an innovation in the design and engineering of ladle cars, optimizing every aspect of the process through the use of advanced technologies, precision measurement tools, and adherence to stringent international regulations.

2. Project Objectives and

Application Context

Project Objective:

-

To design a ladle car that operates safely and efficiently, ensuring high-quality standards and compliance with international regulations.

Application Context:

-

Utilized in steel mills for the transportation and handling of molten metal in environments characterized by high temperatures and significant mechanical and thermal loads.

3. Regulatory References

Our design adheres to a comprehensive set of international standards to ensure safety and compliance:

Structural and Calculation Standards:

-

Eurocodes (EN 1990 - EN 1999): Foundation for calculating metal structures and applied loads.

-

EN 13001 & FEM 1.001: Guidelines for structural calculations and verifications, especially for lifting equipment.

Specific Standards for Ladle Cars and Safety:

-

EN 14477: Safety requirements for ladles in steel mills.

-

ISO 16881: Safety specifications for ladle transfer systems.

Standards for Components and Assemblies:

-

EN 1090: Execution and control of steel and aluminum structures.

-

ISO 5817: Acceptance criteria for welding quality.

-

EN 10025: Structural steel specifications.

Rail Transport Standards (if applicable):

-

EN 15663 & UIC 505-1: Rail transport specifications, load conditions, and vehicle safety.

4. Design and Analysis Software

We leverage a suite of powerful software tools to ensure a robust and optimized design:

(Software and their Purpose)

-

BricsCAD Ultimate3D: modeling and technical drawings

-

Mech-Q: Design of mechanical components (gears, bearings, transmissions)

-

FE-System Means V13: Mechanical analysis and simulations

-

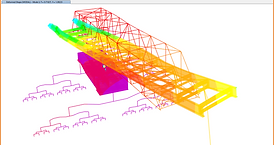

CSI SAP2000: Structural analysis, stress verification, compliance with Eurocodes

-

MATLAB & Simulink: Dynamic and thermal simulations, system control

-

Newton Professional: Granular material behavior simulation for efficient ladle emptying

-

CorelDRAW Technical Suite:Technical documentation, diagrams, and professional presentations.

5. Control and Verification

Instruments

We employ a comprehensive set of measurement instruments for quality control and verification throughout the process:

-

3D Laser Scanners (Freescan Combo Plus & Einscan Pro HD – Geomagic): Geometric verification by comparing the "as-designed" model with the "as-built" product. Also used for deformation monitoring during service.

-

Hardness meter: Measuring the hardness of materials to confirm mechanical properties.

-

Roughness meter: Assessing surface roughness for operational efficiency and wear reduction.

-

Ultrasonic Thickness and Defect Detectors: Checking refractory coatings, corrosion protection, and detecting internal flaws.

-

Sound Level Meter: Analyzing noise levels for regulation compliance and operational anomalies.

-

Thermal Camera: Monitoring temperature distribution to detect overheating or thermal dispersion issues.

6. Integration of the Design

Process and Control

Our design process is a tightly integrated system:

-

Design Phase: CAD and analysis software used to develop a 3D and structural model that complies with applicable standards.

-

Simulation and Analysis: MATLAB/Simulink and CSI SAP2000 applied to simulate mechanical and thermal behavior, verifying loads and stresses.

-

Quality Control and Verification: Control instruments (3D scanners, durometer, ultrasonic devices, etc.) used for "as-built" verification and real operating condition monitoring.

-

Documentation and Reporting: CorelDRAW Technical Suite utilized for preparing technical reports and project documentation.

7. Conclusions

-

Compliance and Safety: The integration of regulatory standards, design software, and verification instruments ensures the creation of a safe, efficient, and internationally compliant ladle car.

-

Innovation and Continuous Monitoring: Advanced modeling and control technologies enable continuous quality monitoring, reducing the risk of failures and enhancing operational performance.

-

Process Flexibility: The use of multidisciplinary tools allows the design process to adapt to specific operational needs and ensures effective management throughout the product lifecycle.

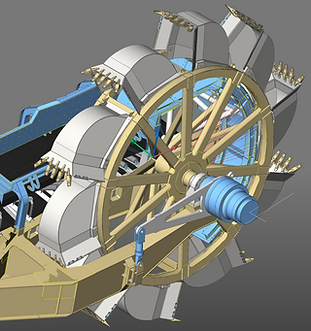

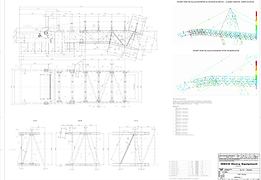

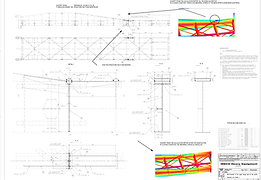

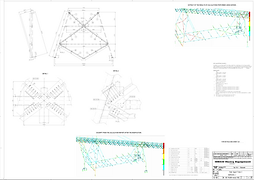

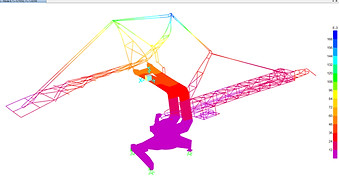

Design and Optimization of a Bucket Wheel Stacker/Reclaimer: A comprehensive Approach

1. Introduction

Bucket wheel stacker reclaimers are indispensable machines for handling bulk materials on a large scale. Their design requires a multidisciplinary approach, integrating engineering expertise, accurate analysis, and rigorous quality control.

2. Phase 1: analysis of the

Material to be Handled

The correct design of a bucket wheel stacker reclaimer largely depends on a thorough knowledge of the properties of the material to be handled. In this phase, we focus on:

-

Angle of repose: Determines the maximum inclination of a pile of material without it sliding. This parameter is fundamental to correctly size the bucket wheel, conveyor belts, and storage systems.

-

Particle size distribution: Analyzes the distribution of particle sizes of the material. Particle size influences the flow of material, the wear of components, and the transport capacity of the machine.

-

Density, humidity, and abrasiveness: These properties influence the weight of the material, its tendency to adhere to surfaces, and the wear of components.

Tools and Techniques:

-

Direct measurements: We use specific tools to measure the angle of repose and the particle size distribution of the material.

-

3D scanners: We acquire 3D models of the material to analyze the shape, size, and distribution of particles.

-

Geomagic Enterprise: We use this software to process the data acquired with 3D scanners and obtain detailed information on the particle size distribution and shape.

-

MATLAB: We use MATLAB for statistical analysis of the data and the creation of mathematical models that describe the behavior of the material.

3. Software for Modeling and

Analysis

-

BricsCAD Ultimate: The starting point for detailed 3D modeling of the structure, mechanical components, and general assembly. Its versatility and compatibility with other CAD formats make it a valuable tool for creating technical drawings and managing documentation.

-

CSI SAP2000: Fundamental for structural analysis, verifying the strength and stability of the machine under static and dynamic loads. It allows simulating the behavior of the structure in different operating conditions, ensuring safety and reliability.

-

Sidewinder: Essential for simulating the flow of material through the bucket wheel and conveyor belts. It allows optimizing the design to maximize transport efficiency and reduce component wear.

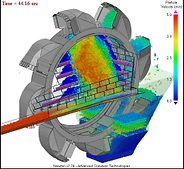

-

PAX FEA: Used for finite element analysis (FEA) of critical components, such as the bucket wheel, the boom, and the support systems. It allows evaluating the stresses, deformations, and durability of the components, optimizing their design to withstand the most severe operating conditions.

-

Newton Professional DEM: An added value for simulating the behavior of granular and particulate materials within the machine. It allows studying the flow of material in the bucket wheel, conveyor belts, and discharge points, optimizing the design to reduce friction, wear, and material accumulation.

4. Quality Control and

Measurement Tools

Our commitment to quality is reflected in every phase of the process, from design to production and installation. We have a wide range of state-of-the-art measuring instruments to ensure compliance with the highest standards:

-

3D scanners with refracted and laser light: Precise acquisition of the geometry of the components for comparison with 3D models and verification of dimensional conformity.

-

Metal analyzer: Chemical analysis of materials to guarantee quality and compliance with specifications.

-

Ultrasound flaw detector: Detection of internal defects in structural components, such as welds and castings, to ensure integrity and safety.

-

Ultrasound thickness and hardness meter: Verification of the thickness and hardness of materials to ensure compliance with specifications and wear resistance.

-

Roughness meter: Control of the surface roughness of the components to ensure functionality and durability.

-

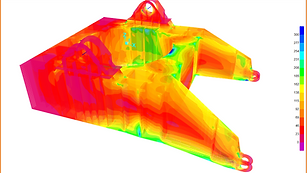

Thermal camera: Detection of thermal anomalies in mechanical and electrical components during operation, allowing potential problems to be identified and preventing failures.

-

Oscilloscope: Analysis of electrical signals in control and monitoring systems to ensure correct operation and stability.

-

Sound level meter: Measurement of noise levels during operation to ensure compliance with environmental regulations and operator safety.

5. Continuous Improvement

Our approach to design is oriented towards continuous improvement. We use the data collected during tests and measurements, including thermal images acquired with the thermal imager, to optimize the design, improve performance, and increase the reliability of our machines.

6. Conclusions

The design of a bucket wheel stacker reclaimer is a complex challenge that requires specialized skills, advanced software, and rigorous quality control. Our integrated approach, which combines material analysis, 3D modeling, structural analysis, material flow simulation, FEA, thermography, and meticulous quality control, allows us to offer customized, efficient, and reliable solutions for the bulk material handling needs of our customers.

Integrated Design of a Chemical Plant: Engineering and Regulations

1. Introduction

Project Objective:

Develop a safe and efficient chemical plant, focusing on mechanical and structural design, as well as the verification of pressure vessels and heat exchangers.

Integrated Approach:

Use advanced software tools (Microtecno MT-3, BricsCAD Ultimate, Mech-Q, CSI SAP2000, V Means13) and inspection instruments (3D scanners, hardness meter, UT detectors, thermal camera, etc.) to ensure regulatory compliance and high-quality "as-built" verification.

2. Design Tools and Software

-

Microtecno MT-3: Calculation and verification of pressure vessels and heat exchangers in compliance with PED, ASME, and EN 13445.

-

BricsCAD Ultimate: 3D modeling and detailed technical drawings.

-

Mech-Q, CSI SAP2000, and V Means13: Structural and mechanical analysis for dimensioning and verifying plant robustness.

-

Inspection Instruments: 3D laser scanners, durometer, roughness meter, UT defect detectors, sound level meter, and thermal camera for "as-built" monitoring and quality control.

3. Applicable Regulations

For Pressure Vessels and Heat Exchangers:

-

PED 2014/68/EU: Regulates design and commissioning of pressure equipment in the EU.

-

ASME BPVC Section VIII: U.S. standard for pressure vessel design, widely adopted internationally.

-

EN 13445 & EN 13480: Specifications for pressure vessels and industrial piping.

For Structural and Mechanical Components:

-

Eurocodes (EN 1990 - EN 1999): Fundamental for structural calculations.

-

EN 1090, EN 10025, ISO 5817: Standards related to welding and structural materials.

For Safety and Environmental Protection:

-

Seveso Directive: Managing risks of major industrial accidents.

-

ATEX Directive: Equipment design for potentially explosive atmospheres.

-

Fire and Environmental Regulations: Emission control, waste management, and environmental protection.

-

REACH & CLP: Chemical substance classification and labeling regulations.

For Electrical and Automation Systems:

-

IEC Standards: International safety standards for electrical installations.

4. Integration of Design and Regulations

Design Phase:

-

Modeling and Analysis: Using CAD and simulation software to develop a 3D and structural model that complies with technical regulations (PED, ASME, Eurocodes).

-

Regulatory Verification: Performing calculations and simulations (with Microtecno MT-3, CSI SAP2000, etc.) to ensure all components meet required standards.

Control and Validation Phase:

-

"As-Built" Verification: Using 3D scanners and measurement instruments to compare the final product with the design model, ensuring compliance with tolerances and specifications.

-

Documentation and Certification: Preparing technical reports and full documentation for certification approval (PED, ASME, etc.).

Continuous Feedback:

-

Operational monitoring (with thermal cameras, sound meters, etc.) enables early detection of anomalies and allows design improvements, ensuring ongoing regulatory compliance.

5 Benefits of the Integrated Approach

-

Safety and Reliability: Advanced analysis and inspection tools ensure a safe and robust plant.

-

Efficiency and Cost Reduction: Integrated workflow minimizes errors and design time, optimizing resources and costs.

-

Regulatory Compliance: Strict adherence to international standards facilitates certification and guarantees operational safety.

-

Continuous Monitoring: "As-built" control and in-service monitoring enable prompt intervention in case of issues.

6. Conclusions

The integration of advanced design tools with strict regulatory compliance enables the development of a state-of-the-art chemical plant.

A multidisciplinary approach ensures plant safety, efficiency, and compliance while reducing risks and enhancing final product quality.

Continuous monitoring and feedback provide a strategic advantage for plant optimization and long-term maintenance.

We believe communication is fundamental

Cutting-edge, multi-language portable smart voice translators allow us to communicate in 40 foreign languages.

The technology of Vasco Translator and of Timekettle helps us removing language barriers.

On site, on the phone, in a meeting, we take advantage of AI for the best instant understanding and talking with our customers.